The Plastic Surgery 03 Vase is the defining icon of 91-92, celebrating individuality through bold design. Its signature S-curve exudes confidence, offering a sculptural statement that transcends conventional beauty standards. Just as every person has a unique form, this vase embraces fluidity and imperfection, inviting you to appreciate diversity through design.

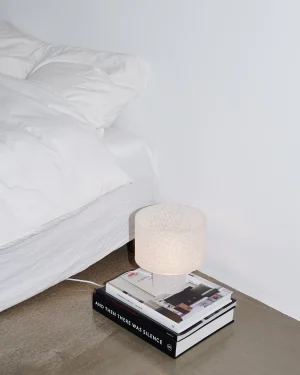

Depending on how light interacts with its surface, the vase reveals unexpected textures and shifting highlights, giving it a dynamic, living presence. Its transformative play with light ensures that no two moments—or perspectives—are ever the same.

Available in a range of sizes and colors, the Plastic Surgery 03 Vase allows for personal expression while maintaining its powerful design identity. Its bold curves make it a centerpiece that commands attention while sparking conversation.

Key Features:

Bold, Iconic Design: Signature S-curve celebrating individuality and fluid forms.

Ever-Changing Aesthetic: Surface texture evolves with shifting light, creating a dynamic, sculptural presence.

Customization Options: Available in various sizes and colors for personalized style.

Sustainable Production: 3D printed in Copenhagen using eco-conscious materials.

Own the Plastic Surgery 03 Vase, where design meets identity, and art becomes a celebration of diverse forms and personal expression.

Designed and 3D printed in Copenhagen, each vase is created with a commitment to sustainable production, blending cutting-edge technology with thoughtful design.

| Dimensions LxWxH | 10x10x29cm (4x4x11'') |

|---|---|

| Piece Weight (kg) | 0.1 |

| Production Year | |

| Material | |

| Discipline | |

| Color | Black, Marzipan, Postbox Red, Purple, Slushy Pink, Transparent, Transparent/Blue, Ultramarine Blue |

| Design Class |