Inrō interprets the unique language and design vision of Atelier Nuanda, reflecting the careful study and mastery of complex development techniques that give shape to the new collection, overcoming production limitations.

The ancient Japanese containers made by expert craftsmen of the Sengoku period (1467-1615), from which the name Inrō derives, become an element of study for the atelier.

Consisting of small stacked elements held together at the ends by a bead (ojime) and two passing cords, the traditional case was worn and suspended at the waist for the transport of strictly utilitarian objects, later becoming a collectible art object over the centuries.

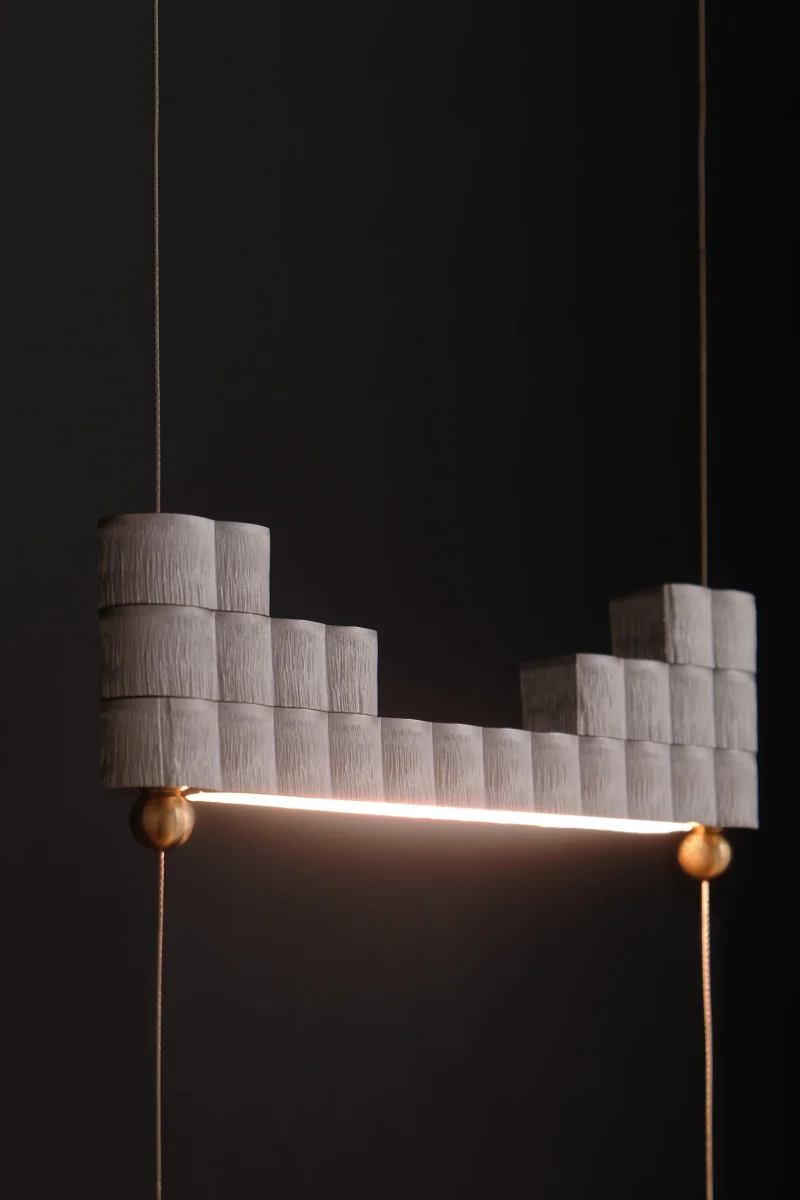

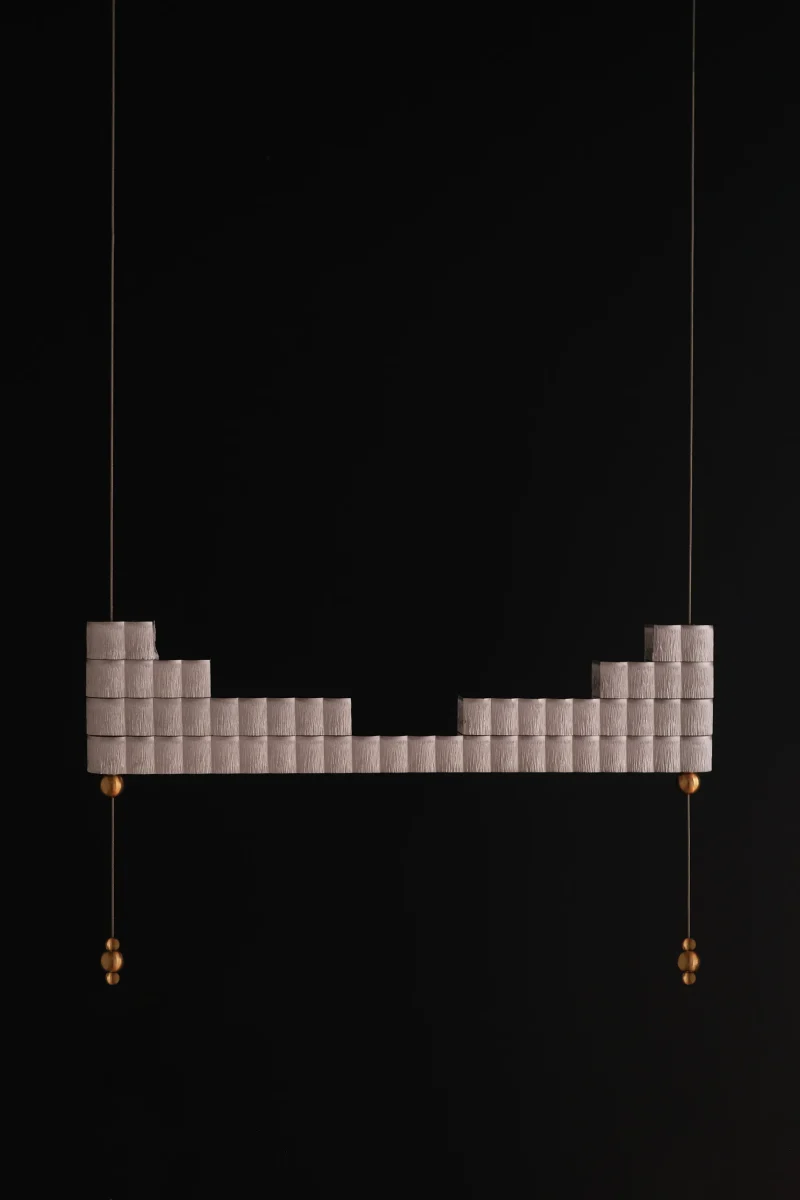

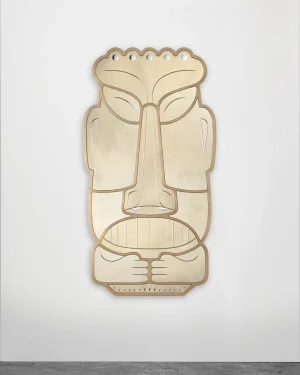

The atelier’s new project is inspired by this ancient object to create a modular lamp, composed of overlapping aluminium bars crossed by suspension cables that electrify the lighting body.

The attention to the choice of materials and their manufacturing process enhances the references to tradition, revisiting ancient forms and decorations, updated and made contemporary thanks to the use of modern tools and techniques.

Natural aluminium, a material used in industrial production for its high physical and mechanical qualities, was chosen by the atelier as the exclusive protagonist of the collection.

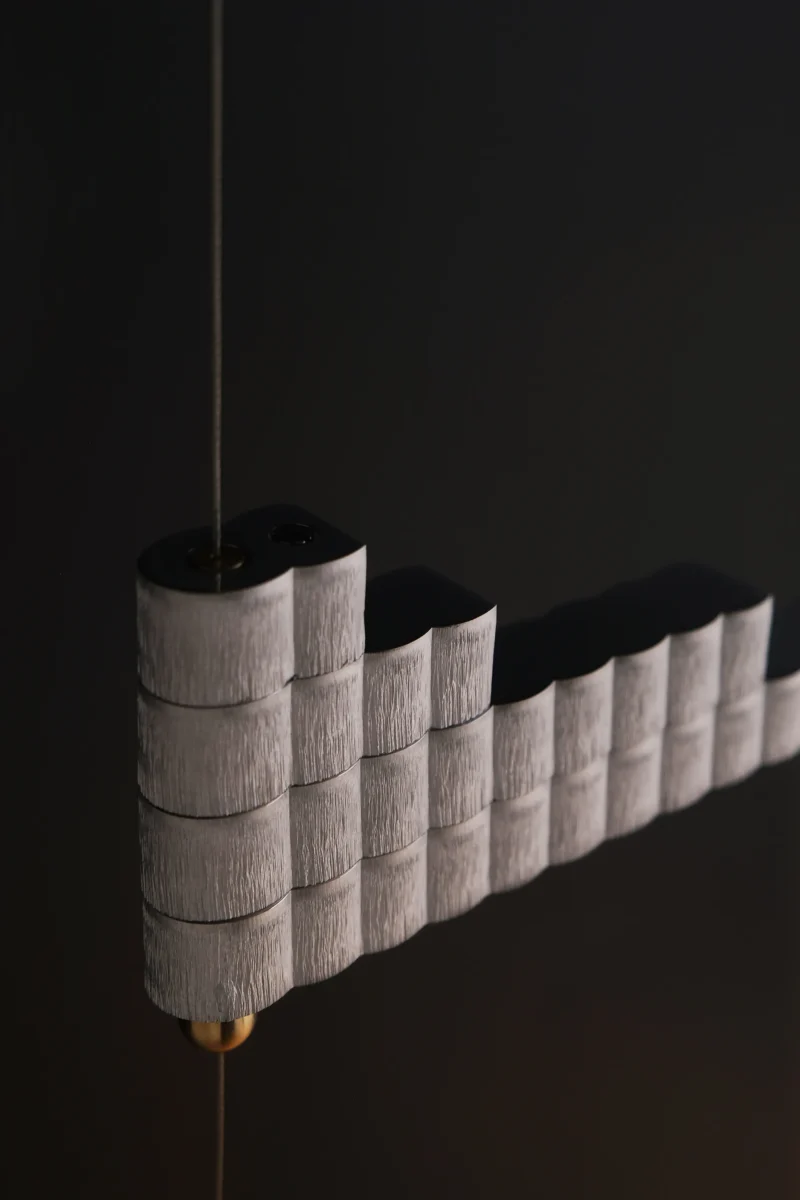

Through research, study and knowledge of the material, tests were carried out on laser cutting, from the type of machinery used to the modification of standard processing parameters, in order to obtain a finish that respected Nuanda’s design vision, bringing to light a new aesthetic that combines experimentation and the exaltation of technological gestures in decoration.

Once processed, the aluminium sheet reveals details that become both finish and decoration, taking technological effort to the extreme and overturning the paradigm of mass production: industrial machinery is used to obtain unique and unrepeatable pieces.

Like fabric moved by the wind, the voluptuous surface dissolved by the laser crystallises, cooling to create an extremely resistant and waterproof structure that defines a unique aesthetic, bringing to light the purity of natural aluminium, which has become a new and exclusive industrial finish.

All stages of production have been defined and monitored step by step with specialised technicians to identify, resolve and optimise production steps, ensuring full awareness of industrial production and accurate development of the finished product.

Thanks to its physical properties, aluminium has a low specific heat, which guarantees complete and effective dissipation of the LED source, safeguarding the efficiency and useful life of the lighting fixture.

Inrō is a modular lamp, suspended by two cables of different polarity that support and power the structure. The two silver-braided cables with steel cores ensure power supply and structural integrity, eliminating the need for an additional power cable.

Each lamp body contains a high-efficiency LED light source with Ra98 for perfect colour rendering. It can be installed with the light source facing downwards, as a power source to illuminate tables and other surfaces, or rotated upwards to illuminate the ceilings of large spaces with indirect light, achieving a softer, more diffused light.

The lamp is available in two different lengths, each of which can be installed individually or inserted into multiple compositions to create even large chandeliers, for unique and diverse scenarios based on customer requirements and the installation location.

Suspension lamps natural aluminium structure

Configurations: Modular system of pendant lamps with LED Ra98 2700K (3 metre suspension cable – available 10 metre on request)

Inrō 192 – Dimensions (each): L19.2 x W2 x H6 cm – Weight: 0.35 kg (each) – 8W powered by low voltage 24V

Inrō 342 – Dimensions (each): L34.2 x W2 x H8 cm (each) – Weight: 0.50 kg – 14W powered by low voltage 24V

(power supply included on the prices – casambi available on request)

The materials used are part of a supply chain and production process focused on sustainability. Untreated natural aluminium is a 100% recyclable material. Laser cutting also eliminates the need for additional finishing processes, thus shortening the production chain and reducing time, pollution, costs and energy consumption.

| Dimensions LxWxH | 84x19x50cm (33x7x20'') |

|---|---|

| Piece Weight (kg) | 1.4 |

| Material | |

| Color | |

| Design Class |