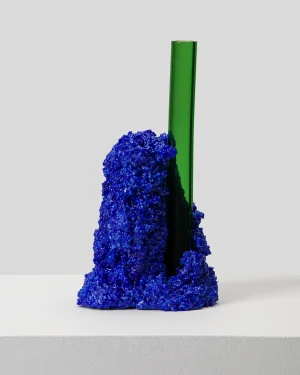

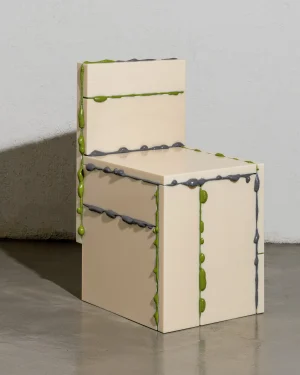

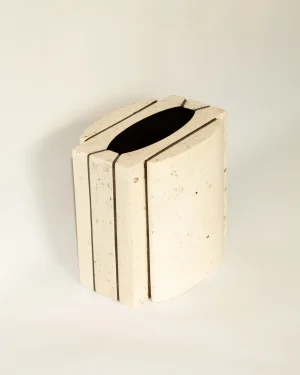

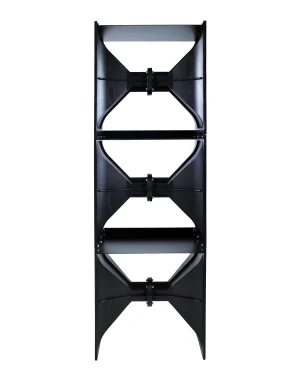

By defining the design process, I aim to explore new possibilities between planning and variables. The B.S.P. series begins with research on how to recycle plastic by-products. The name B.S.P. is inspired by the abbreviation of the B.L.T. club sandwich and stands for By-product, Solvent, and Plastic, which are the materials used in production. As an industrial designer, I focus on the plastic flakes generated while creating various design prototypes using CNC machining and 3D printing. For this project, I tested different amounts of solvent, types of plastic, and reaction times in a physical chemistry lab. I discovered that a specific type of plastic melts in organic solvents after a particular duration. Due to their large surface area, tiny flakes or small parts from failed prototypes dissolve more easily in minimal amounts of solvent. I also made a recycled plastic plate using discarded large pieces. Through this research, I can reinterpret plastic suitable for mass production as a handcrafted material, bonding plastic with by-products. The final product solidifies as the solvent evaporates, creating objects reminiscent of spilled cheese that intrigue viewers and offer a new aesthetic. I designed art furniture using this process, which can be applied to various shapes and colors.

The items in the B.S.P series (By-product, Solvent, and Plastic) are uniquely handmade and should be handled with the utmost care.

Especially, be careful not to bump into the protruding texture.

For indoor use only.

| Dimensions LxWxH | 21x21x112cm (8x8x44'') |

|---|---|

| Piece Weight (kg) | 27 |

| Production Year | |

| Material | |

| Discipline | |

| Color | |

| Design Class |